Induction Sealers

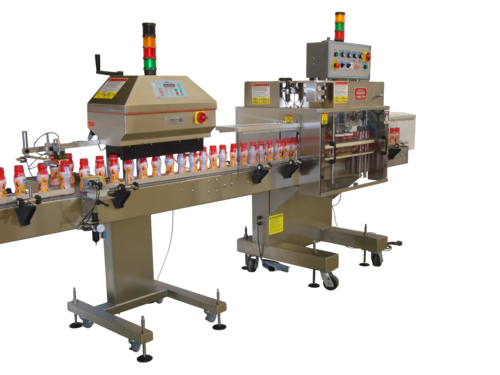

Waterless Induction Cap Sealers. Automate Smart sealers are the industry standard for induction sealing! Three models available to suit all of your production needs.

The AutoMate Induction Sealers are here to suit all of your production needs. KAPS-ALL® created waterless induction cap sealers that are the industry standard! Our induction cap sealers are made to support your business with efficiency, quality, and have been the proven standard for decades.

Our inline induction sealers are ultra-compact, high-efficiency, and very user-friendly. The field strength of the inline induction sealer can accurately be measured with our exclusive SMART-SEAL™ Meter. This state of the art electronic Meter assists in verifying that the sealer is producing the same repeatable sealing field every time, assuring a consistent power output.

Why choose KAPS-ALL® for Induction Sealers?

KAPS-ALL Packaging System, Inc. has been designing and building top of the line sealing machines since 1941. The best available components/engineering are provided with each Induction Sealers giving you long- term, low maintenance bottling, and packaging equipment. Complete bottle orienting, cleaning, filling, capping, sealing and diagnostic systems including.

We have three models that are available for you to change your production line into a dynamic and seamless process!

|

AutoMate AM-100 |

AutoMate AM-250 |

AutoMate AM-500 |

|

Semi-Automatic Small Volume Runs 1,000 Watts Compact Design |

Automatic Industry Standard 2,500 Watts |

Automatic High Volume Runs 5,000 Watts |

AutoMate AM-100: Precision and Versatility

The AM-100, a semi-automatic benchtop induction sealer, leads the pack with its precision and versatility. Designed for research, development, and small-volume runs, the AM-100 delivers 1000 Watts of power in a compact package. It accommodates caps ranging from 5mm to 100mm in diameter, making it a versatile and reliable choice for various applications.

Why it's the Right Choice: The AM-100 strikes a balance between precision and flexibility, making it the perfect solution for businesses with diverse sealing needs. Its compact design and easy operability make it a go-to for smaller-scale production while delivering the precision required for research and development endeavors.

AutoMate AM-250: Industry Standard for Efficiency

Next in line is the AM-250, the original waterless cap sealer and the industry standard for induction sealing. Delivering a robust 2,500 Watts of power at the sealing head, the AM-250 strikes the right balance for small to high-volume production. With over 15 patents, the AM-250 exemplifies advanced design and energy-efficient circuitry.

Why it's the Right Choice: The AM-250 sets the standard for efficiency and adaptability in the world of induction sealing. With its powerful performance and user-friendly features, it caters to a broad spectrum of production needs while ensuring operator safety and ease of use.

AutoMate AM-500: Power and Speed Combined

The AM-500 takes the lead as the epitome of high-speed induction sealing, designed for demanding production requirements. Boasting an impressive 5,000 Watts—five times more powerful than many competitors—the AM-500 allows for exceptionally high conveyor speeds and meets the most rigorous cap sealing demands. Its waterless cap sealing technology sets it apart, making it the most powerful waterless cap sealer on the market.

Why it's the Right Choice: The AM-500 stands as a testament to power and speed, making it an ideal choice for high-volume production with stringent cap sealing requirements. Its cutting-edge features and robust construction ensure efficiency, reliability, and ease of use in demanding industrial settings.

In conclusion, the Automate AM-100, AM-250, and AM-500, represent the pinnacle of excellence in the world of induction sealing. Their innovative designs, energy-efficient features, and user-friendly interfaces make them the top choices for businesses seeking precision, efficiency, and reliability in their induction sealing processes. Choose Automate for a seamless and powerful induction sealing experience tailored to your unique production needs.

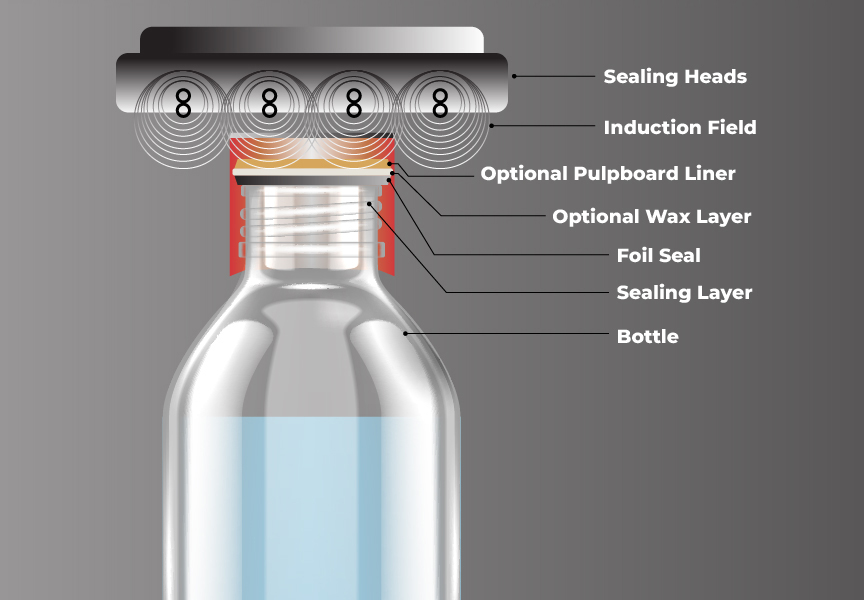

How the Smart-Seal Works for our Induction Cap Sealers

Utilizing the caps pressure on the liner under the cap, the AutoMate Model AM-50, AM-75, AM-150, AM-250 and AM-500 heat the foil seal and sealing layer utilizing an electro-magnetic field through the cap. This method will heat the foil seal and also melt the optional wax layer and allow the polymer film and foil seal to be fused to the container.

This will give a tamper evident hermetic seal when the cap is removed. This process is extremely efficient and fast. The electro-magnetic field produces no heat itself and therefore does not interfere with the product. Sealing rates using this process can be in excess of 40+ bottles per minute for the Semi-Automatic Sealers and 500+ Bottles per minute for the Automatic Sealers.

Evolution of Waterless Cap Sealers

1980's - Before AutoMate

- Water-Cooled Cap Sealers

- High Energy Consumption

- Large, Bulky Design

- Low Sealing Power

- Expensive Price Tag

- Long Delivery Time

- Pumps, Tanks, Fan Belts

Early 1990's - AutoMate - The Originator of the Patented "Waterless Cap Sealer"

- Low Energy Consumption

- Compact Design

- High Sealing Power (2300 Watts)

- Low Cost

- Fast Delivery

- No Pumps, Fan Belts, Water Tanks

2003 - AutoMate SMART-SEAL™, Full-Featured "Waterless Cap Sealers"

- More Sealing Power (1500 - 5000 Watts)

- More efficient, More features, More compact

- Lower price with built-in cap inspection and rejection system

- User friendly

- Protected with over 9 patents and several patents pending

- Sealed / Gasketed Electronics

2005 - Present

- AutoMate is the ONLY source providing Mid to High Power Automatic, and Semi-Automatic models to meet your specific production needs. Only from AutoMate comes time-saving and efficient patented features offered as standard equipment, such as Self-Calibrating Electronics for top performance.

FAQs

Contact KAPS-ALL or a KAPS-ALL Sales Representative. KAPS-ALL's experienced staff can guide you in choosing the model that fits your current and future needs.

You can purchase a KAPS-ALL product directly from KAPS-ALL or from a local KAPS-ALL Sales Representative. KAPS-ALL offers a free demonstration and testing of your product before you buy at no cost or obligation.

KAPS-ALL simple patented machine designs can usually be serviced by your own staff. KAPS-ALL's local representatives and factory technicians are also available.

A complete inventory of parts are available for immediate shipment.