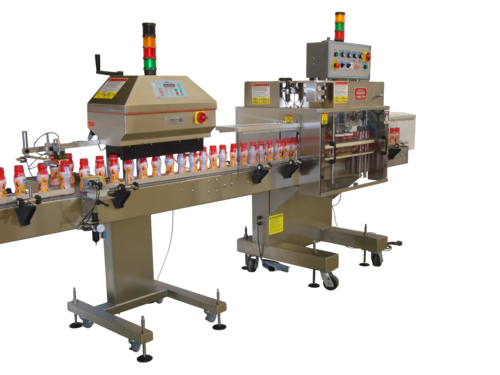

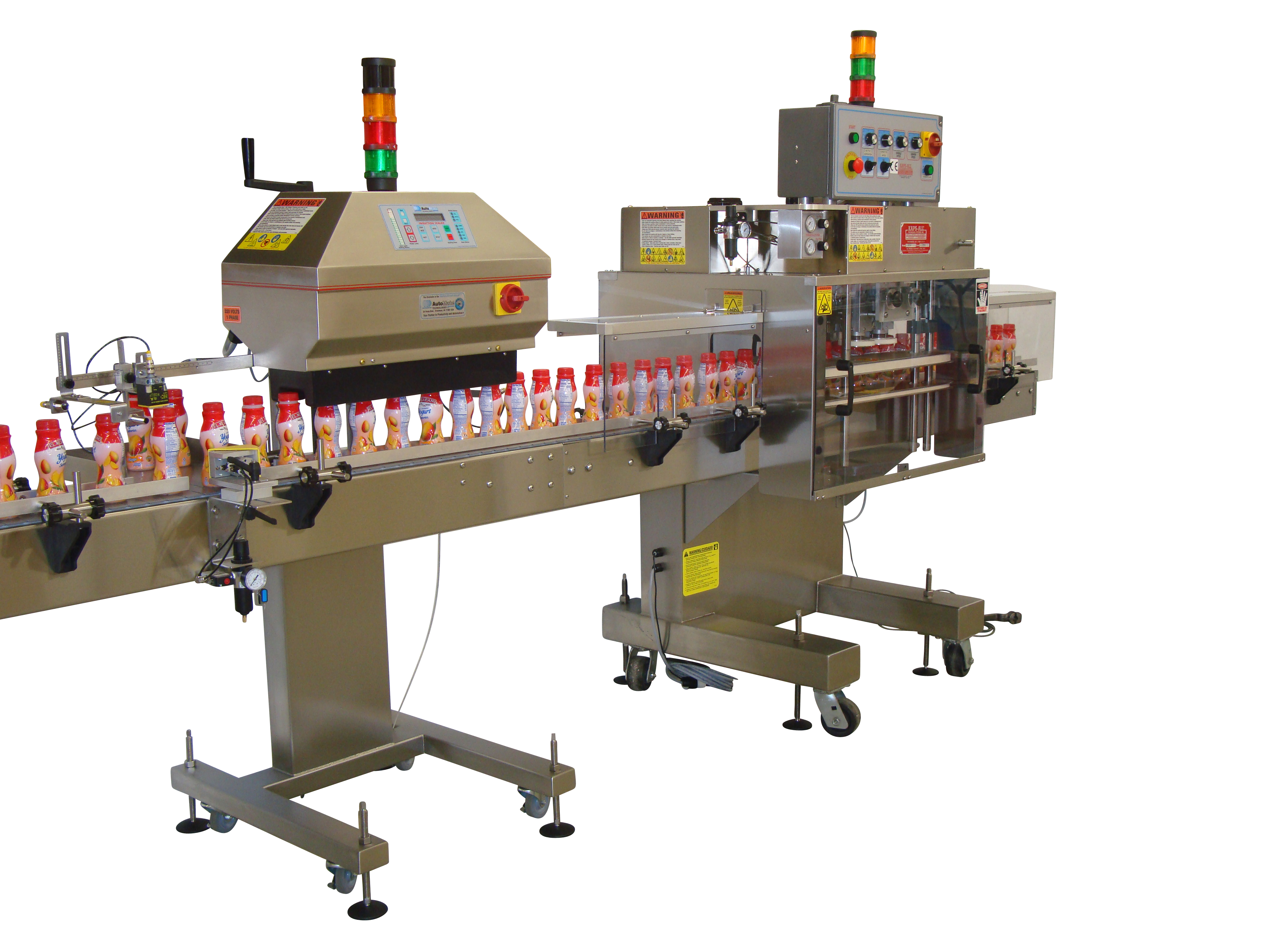

AM-250 Automatic Induction Sealer

Induction Sealers, Foil Sealers, and Induction Cap Sealers

Automatic Induction Sealing Machine

Patented design energy efficient foil sealing systems come complete and ready to use pre-assembled.

AutoMate AM-250 is the industry standard for Induction Sealing. This is the original Waterless Cap Sealer. The Model AM-250 is the right choice for small to high volume production. The ultra-compact machine delivers 2,500 Watts of power at the sealing head!

Looking for induction sealers? Why you might consider the AM-250

Induction sealers are specialized machines that use electromagnetic induction to seal containers with a foil seal. The AM-250 model is an advanced induction sealer that boasts a patented design and energy-efficient circuitry. With over 15 patents, the sealer comes complete and ready to use pre-assembled. Unlike other sealers on the market, the AM-250 does not require water-cooling, radiators, pumps, or air cooling. Its efficient advanced circuitry increases power and minimizes waste heat production.

The AM-250 is highly versatile induction cap sealing machine and can seal a wide range of cap sizes, up to 70mm in diameter, and has sealing heads available for up to 120mm and specialty caps. The machine is equipped with load-sensitive operator assist LED bar graphs for easy set-up and operating status. The LED "Heart-Beat" monitoring simplifies servicing, while consecutive and excessive fault detection ensures maximum efficiency.

The induction cap sealer is protected by sealed, gasketed electronics, providing protection for demanding environments. It also comes with a built-in power save mode that minimizes energy consumption. The sealer's mini-computer keeps track of basic statistics, including total bottles sealed, sealing power used, batch and lot numbers, date, faults encountered, time, and more. The AM-250 is user-friendly, with multi-language screens and recipe storage. It is also equipped with interlocking stainless steel safety guard switches and an easy-to-read two-line digital full text display.

Induction Sealer

KAPS-All is the leader in Induction Sealers & Induction Sealing Machines

Induction Sealing Machine

- State of the art patented surface mount electronic system eliminates the need for water-cooling, radiators, pumps, etc., making this unit one of the most efficient induction cap sealers around.

- Induction sealing for a wide reange of cap sizes up to 70mm diameter (sealing heads available for up to 120mm and specialty caps).

- Patented design energy efficient induction foil sealing systems come complete and ready to use pre-assembled. Protected by over 15 patents.

- Screens in English, Spanish and French.

- Sealed, gasketed electronics provides protection for demanding environments.

- LED “Heart-Beat” monitoring for simplified servicing. No moving parts.

- Load sensitive operator assist “LED BAR GRAPH”, for easy set-up and operating status (PATENTED).

- Consecutive and excessive fault detection.

- Built in power save mode minimizes energy consumption.

- Efficient advanced circuitry for increased power and minimizes waste heat production (Not air cooled like others on market).

- Portable one piece welded frame with locking swivel castors and stainless steel leveling screws with floor pads.

- Fast easy changeovers, height adjustment-accommodates 1” tall to 14" tall containers with a simple hand adjustment.

- Standard digital bottle counter and rate meter (bottles per minute).

- Mini-computer keeps track of basic statistics which include: A) Total bottles sealed B) Sealing power used C) Batch and lot Numbers D) Date E) Faults encountered F) Time G) Multi-Language Screens H) Conveyor speed I) User friendly menus and recipe storage J) And more.

- Loss of current indicator. Internal circuitry provides monitoring of sealing head power. Automatically adjusts power as needed.

- Interlocking stainless steel safety guard switches.

- Easy to read two line digital full text display. All operator settings including LED indicator lights at your fingertips. Minimizes operator training.

- Main power switch with OSHA lockout for servicing.

- State of the art plug in electronic manifold for sensors to hook up with no wiring required.

- IQ-OQ validation assistance available.

Model AM-250 (more than 2,500 watts of output power at the sealing head where it is used)

This foil sealer is ideal For:

• Ideal For: Small, Medium and Large output production and all industries

Air-Electrical:

205-240V, 1 Phase, 50-60 Hertz (approximately 18 amps maximum).

Size:

- Crated Induction Sealer Machine Weight: 250lbs

- Shipping Measurements Box on Skid 30” x 40” x 42.5”