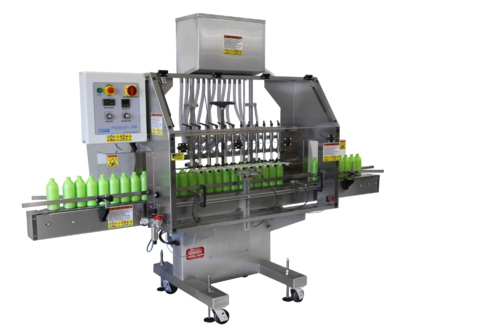

FA-G-E Gravity Filler

Liquid Fillers

FA-G-E Gravity Filler: The Ultimate in Liquid Filling Technology

The FA-G-E Gravity Filler is a fully automatic, microprocessor-controlled, straight-line liquid filling machine, this innovative system is designed for maximum efficiency and versatility. Whether your containers are glass, plastic, or metal, this machine handles it all.

Superior Performance

The FA-G-E Gravity Filler distinguishes itself with its ability to handle all free-flowing liquids, excelling with thin, foaming products. This machine is designed for precision, delivering consistently accurate and repeatable results. It’s ideal for all liquid filling applications, keeping pace with your production requirements whether operating separately or integrated into a complete packaging system.

Unmatched Features

At no extra charge, the FA-G-E Gravity Filler comes with an impressive array of standard features. It can accommodate a bottle range from 1 3/4” high to one-gallon containers of glass, plastic, and metal. Our filling machine utilizes all stainless steel pressure/gravity filling nozzles and is equipped with flexible FDA plastic tubing. All product contact parts are either stainless steel or plastic, ensuring durability and compliance with safety standards.

The machine is housed in a standard one-piece welded construction cabinet and includes stainless steel 20-gallon supply and upper tanks. The system is microprocessor-controlled for user-friendly operation, and the gating system is a fully adjustable, pneumatic stainless steel cylinder bottle setup. Four heavy-duty casters ensure portability, and the machine features a fill cycle counter and a no-bottle-no-fill safety switch. The entire system requires minimal conveyor space.

Advanced Customization Options

To further enhance its functionality, we offer a range of options for the FA-G-E Gravity Filler. These include additional stainless steel nozzle heads, a 7 1/2’ stainless steel conveyor bed complete with an electronic variable speed drive, an air-driven double diaphragm polypropylene pump, and options for stainless steel cabinet and table plate construction.

Additionally, we offer a stainless steel drip pan for collecting drippings from nozzles, stainless steel covers for the lower and upper tanks, and conveyor extensions in stainless steel construction. To cater to your specific needs, we also offer bottle neck clamping options for up to twelve nozzles.

Shipping and Handling

For secure transportation, we bolt the machine to a heavy-duty wooden skid. When shipped on a common carrier, the machine is crated to ensure safety. If you prefer to pick up the machine with your own truck, please let us know if you need the machine crated.

Technical Specifications

The FA-G-E Gravity Filler operates on 110V, 1 Phase, 60 Cycle power supply and requires 1-2 cu/ft per min. 90psi of air. The base crated weight of the machine is 850 lbs, and its crated dimension is 8’x4’x7’4”.

Join the ranks of businesses worldwide that trust Kaps-All Packaging Systems for their liquid filling needs. With the FA-G-E Gravity Filler, state-of-the-art components offer maximum performance, reliability, and versatility to meet and exceed your production requirements. Experience the ultimate in liquid filling technology today.

Features:

The Model FA-G Gravity Filler comes equipped with the following standard features at no charge.

- Bottle range of 1 3/4” high to one-gallon glass, plastic and metal containers.

- For all free flowing liquids.

- All stainless steel pressure/gravity filling nozzles

- Flexible FDA plastic tubing.

- All product contact parts to be stainless steel or plastic.

- Standard one piece welded construction cabinet.

- Stainless steel 20 gallon supply tank and 20 gallon gravity upper tank.

- Standard stainless steel upper supply tank float level sensor for pneumatic pump.

- Totally adjustable pneumatic stainless steel cylinder bottle gating system.

- Four (4) heavy duty casters for portability.

- No bottle-no fill-safety switch standard.

- Standard fill cycle counter.

- Only one main moving part.

- No changeover parts for all similar neck finish containers.

- Requires minimal conveyor space (44”; 59” with control panel).

- Head rack, vertical columns, height adjustment screw, etc., to be stainless steel standard.

- Microprocessor controlled for ease of use.

Ideal For:

All liquid filling applications. Excellent with thin foaming products.

The fillers offer accuracy, repeatability and ease of use with little or no changeover parts State-of-the-art components offer maximum performance, reliability and versatility to keep pace with your production requirements. FILLS-ALL fillers can operate separately or can be integrated into a complete packaging system.

Air-Electrical:

-110V, 1 Phase, 60 Cycle

- Air: 1-2 cu/ft per min. 90psi.

Size:

- Base Crated Weight: 850 lbs

- Crated Dimension: 8’x4’x7’4” W