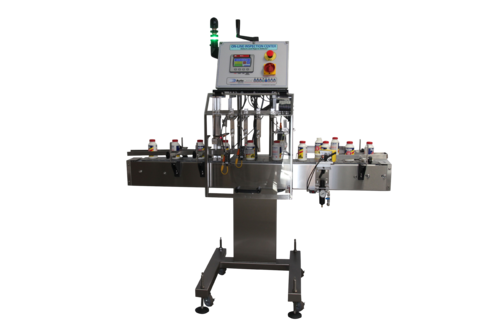

AM-DA Quality Control Center

Quality Control

AutoMate Technologies Diagnostic Inspection Center allows for non Contact / Non Destructive Testing and Rejection for multiple specifications in one center.

- Bottle Counter and Rate Meter Module (Standard).

- Conveyor Speed Monitor with encoder and alarm Module (Standard).

- Missing Cap Detector Module (Standard).

- Exclusive user friendly Allen Bradley color touch screen controls for ease of set up/operation.

- Allen Bradley PLC

- Solid one piece heavy duty welded frame on swivel castors with S.S. leveling screws. Fits over existing conveyor complete with effortless linear height adjustment.

- Exclusive customized sensor modules complete with fully adjusting stainless steel patented clamps to adjust from one container size and cap size to another with calibrated controls, dials and scales for ease of set-up.

- Outputs and controls for optional reject bottle system.

- Multi-level password protected

- Capable of holding 50 recipes.

- S.S. guarding/Lexan door with interlocking safety switches.

- On screen event data and fault counters.

- Non-Contact/Non-Destructive Testing.

- Numerous inspection modules available to complete the detection/inspection and rejection of defects for your exact needs.

- Custom inspection modules available as needed.

- Consecutive fault indicator with alarm.

- Metric units displayed.

- Input-output diagnostic screens

Air-Electrical:

- 110v AC, 1Phase, 50/60 hertz

- Less than 1 CFM of air at 60 PSI used for rejection

Size:

- 3’ x 3’ x 3’ Box on Skid

- 120 lbs. Shipping weight