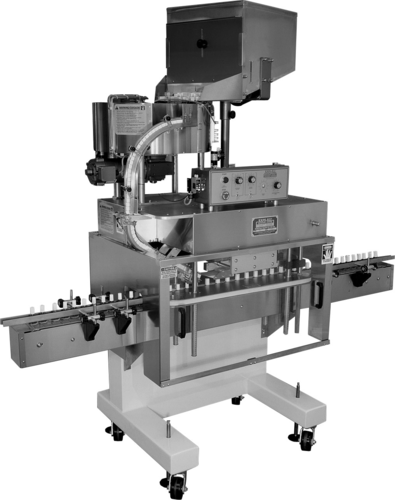

BC8 Overcapper / Lidder

Cappers, and Capping Machines

BC8 Overcapper / Lidder: Unmatched Speed and Versatility for Over Capping

Introducing the Model BC8 Portable Over Capper / Lidder from Kaps-All Packaging Systems. This fully automatic machine sets the benchmark for over capping and lidding operations, offering exceptional speeds of up to 400 bottles per minute. With a compact design that requires only 44" of line space, the BC8 delivers unmatched performance without compromising on efficiency. It effortlessly handles a wide range of over caps, lids, and fitments of all materials and styles, accommodating cap diameters from 13mm to 70mm.

Enhanced Flexibility with Portability

The BC8's portability allows for seamless integration into various production lines, offering unparalleled versatility for automatic over capping and lidding applications. Designed to meet the needs of different industries, this machine handles metal, glass, or plastic containers, including low jars, vials, and even large 2-1/2 gallon containers. Its adaptability ensures it can effectively address your packaging requirements across different product lines.

Reliability and Precision

The BC8 Over Capper / Lidder comes equipped with a comprehensive set of standard features, reflecting our commitment to providing top-tier machinery. With a two-year guarantee on all parts, we prioritize durability and reliability to ensure your packaging operations run smoothly. The stainless steel 7’6” conveyor frame, reinforced with patented nylon and stainless steel components, guarantees robustness and longevity.

Our patented design eliminates the need for changeover parts, making the BC8 compatible with a wide range of standard caps, container shapes, and sizes. Calibrated settings enable quick and repeatable changeovers, streamlining your production processes. Stainless steel guarding of the upper drive section enhances safety, while the stainless steel bottle gripper belt housings, belts, and drives ensure secure and efficient operation.

User-Friendly Design for Easy Maintenance

The BC8 is designed with user-friendliness and maintenance in mind. It features electronically controlled variable speed drives, enabling seamless adjustments to suit your specific requirements. All electrical components adhere to Nema 12 standards, ensuring safe and reliable operation. With four swivel wheels, the machine is easily portable and maneuverable within your facility. Mounting facilities are provided for using a second set of bottle gripper belts, maximizing versatility.

The one-piece solid welded construction cabinet is epoxy painted, promoting cleanliness and simplifying maintenance. Stainless steel machine leveling screws with floor pads ensure stability and easy setup. All parts are modularized for quick replacement, minimizing downtime and reducing the need for extensive tools. Stainless steel bolts and fasteners are used throughout the machine, enhancing its durability and longevity. Interlocking safety switches on the Lexan guarding enclosure guarantee that the machine will not run unless the doors are securely closed, prioritizing operator safety.

Customizable Options for Tailored Performance

Enhance the capabilities of your BC8 Over Capper / Lidder with our range of optional features. Opt for a stainless steel frame and cabinet for increased durability and a polished aesthetic. Nickel or chrome plating is available for visible painted surfaces above the conveyor, adding a touch of elegance to your machine. Additional options include motorized capper head height adjustment, Mini-L stainless steel low-profile hopper/elevator, stainless steel bulk elevator, conveyor extensions, and (IQ-OQ) complete installation and operational qualification protocol documentation. Customize your machine to achieve optimal performance and efficiency.

Unparalleled Speed, Versatility and Reliability

The BC8 Cap Over Capper / Lidder operates on a 220V, 3Ph 50/60Hz power supply (NEMA 12) and requires an air supply of 2 to 4 cubic ft/min. With a base machine dimension of 44", it is compact and space-efficient. When crated, the machine measures 8' L x 5' W x 6' 8" H and weighs 1600 lbs.

Experience unparalleled speed, versatility, and reliability with the Model BC8 Portable Over Capper / Lidder from Kaps-All Packaging Systems. Invest in this cutting-edge machine to elevate your over capping and lidding operations to new heights.

Features:

THE MODEL “BC8” SEMI-AUTOMATIC CAPPER COMES EQUIPPED WITH THE FOLLOWING STANDARD FEATURES AT NO CHARGE:

- Two full-year guarantee on all parts.

- Stainless steel 7’6” conveyor frame DC variable speed drive with a 4 1/2” wide Delrin chain with stainless steel pins, stainless steel drive and idler shafts with patented reinforced nylon and stainless steel conveyor rail posts, stainless steel conveyor end guards and non-corrosive drive and idler conveyor top chain sprockets (left to right travel standard). Note: (Machine also can be purchased without conveyor).

- Stainless steel enclosure with Lexan doors on front and back enclosing spindle and gripper section down to conveyor.

- Can handle cap diameter from 8mm to 120mm standard flat caps and vials to 2-1/2 gallon containers.

- Patented design eliminates need for changeover parts for a wide range of standard caps, container shapes and sizes.

- Calibrated settings allow for ease and repeatability of changeovers.

- Stainless steel guarding of upper drive section.

- One pair of stainless steel bottle gripper belt housings complete with belts and drives.

- All stainless steel bottle gripper belt and spindle shafting.

- All electronically controlled variable speed drives for ease of adjustments.

- All Nema 12 electrical components.

- Portable on four swivel wheels for easy maneuvering.

- Mounting facilities provided for using a second set of bottle gripper belts.

- One-piece solid welded construction cabinet epoxy painted for both cleanliness and easy maintenance.

- Stainless steel machine leveling screws with floor pads.

- All parts modularized for quick replacement. Little to no tools required.

- All stainless steel bolts and fasteners throughout.

- Interlocking safety switches on Lexan guarding enclosure so machine will not run unless doors are closed

Ideal For:

- Caps of all materials from 8mm-120mm.

- Vials up to 2-1/2 gallon containers

- Speeds up to 400 bottles/minute

Air-Electrical:

- 220V, 3Ph 50/60Hz (NEMA 12)

- Air 2 to 4 cubic ft/min

Size:

- Base Machine Dimension: 44”

- Crated Dimension: 8' L x 5' W x 6' 8" H

- Crated Weight 1600lbs