Liquid Fillers

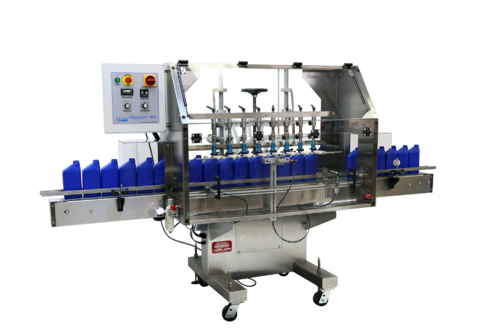

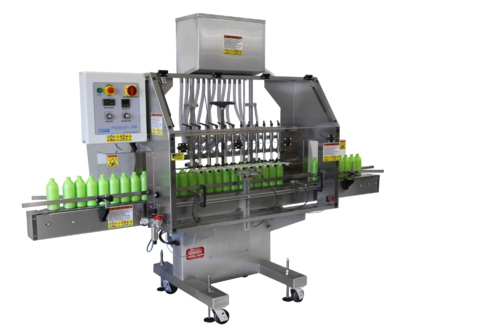

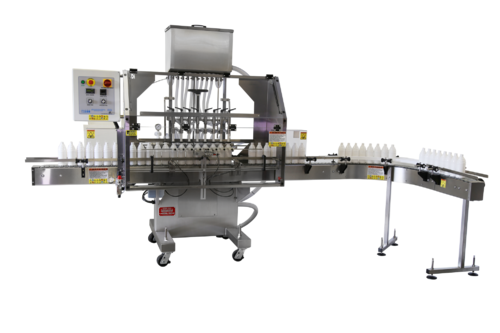

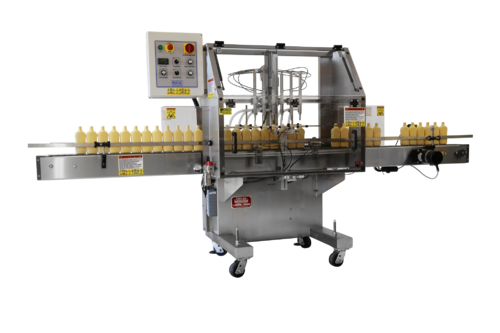

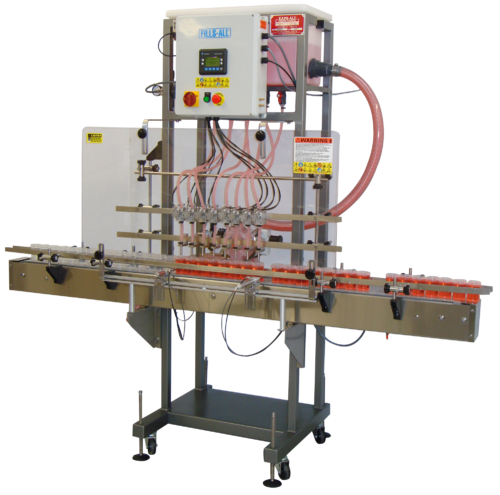

FILLS-ALL™ quality fillers are designed for multipurpose filling operations from free-flowing to viscous products. Only KAPS-ALL® Packaging Systems, Inc. offers a wide range of filling methods and techniques.

FILLS-ALL™ quality fillers are designed for multipurpose filling operations from free-flowing to viscous products. Only KAPS-ALL® Packaging Systems, Inc. offers a wide range of filling methods and techniques.

KAPS-ALL® provides you with the best filling system for your specific application. The fillers offer accuracy, repeatability and ease of use with little or no changeover parts, State-of-the-art components, offer maximum performance, reliability and versatility to keep pace with your production requirements.

FILLS-ALL ™ fillers can operate separately or can be integrated into a complete packaging system. From small 2ml fills to multi-gallon units we have you covered. Filling demonstrations and testing of your products are also available for peace of mind and assurance of your applications success.

Whether you are looking to fill a product with high-viscosity or a water-like product you can count on the FILLS-ALL™ filler to provide you with efficiency and quality. We have 11 fillers to support your filling needs. There are 2 semi-automatic and 9 automatic models that are available for you. If you are looking for a piston filler, gravity filler, pressure filler, benchtop filler, gear pump filler, rotary, positive displacement or volumetric filler- we have it all!

A filler is not just a part of your production line, but it is one of the most important machines to get your production line to be as efficient as possible. Our fillers can have several different options added to propel your machine to the next level! For example, the piston pumps can have <1/2oz (12 cc) * 316 stainless steel pumps all the way up to 64 oz. (1890 cc) 316 stainless steel pumps added. We also have you covered from bench-top single head machines through 24 head models to suit your exact production requirements. Inquire today to learn more to see which of our 11 models is the best for you.

Not sure which is best suited for your needs? See below to explore our 11 models to learn more about each:

Why choose KAPS-ALL® for Liquid Fillers?

KAPS-ALL Packaging System, Inc. has been designing and building top of the line sealing machines since 1941. The best available components/engineering are provided with each Liquid Fillers giving you long- term, low maintenance bottling, and packaging equipment. Complete bottle orienting, cleaning, filling, capping, sealing and diagnostic systems including.

FAQs

Contact KAPS-ALL or a KAPS-ALL Sales Representative. KAPS-ALL's experienced staff can guide you in choosing the model that fits your current and future needs.

You can purchase a KAPS-ALL product directly from KAPS-ALL or from a local KAPS-ALL Sales Representative. KAPS-ALL offers a free demonstration and testing of your product before you buy at no cost or obligation.

KAPS-ALL simple patented machine designs can usually be serviced by your own staff. KAPS-ALL's local representatives and factory technicians are also available.

A complete inventory of parts are available for immediate shipment.