Foil Sealers

Waterless Foil Sealers. Automate Smart sealers are the industry standard for foil sealing! Three models available to suit all of your production needs.

The Originator of The "WATERLESS CAP SEALER"

Automatic & Semi-Automatic Portable and Hands-Free Induction Foil Sealers

We offer full-featured, field-proven Waterless Cap Sealers Developed for Demanding Production Lines with on-line monitoring systems.

Waterless Foil Sealers. Automate Smart sealers are the industry standard for foil sealing! Three models available to suit all of your production needs. For all applications, contact Kaps-All for Waterless Induction Cap Sealing Systems.

Why choose KAPS-ALL® for Foil Sealers?

KAPS-ALL Packaging System, Inc. has been designing and building top of the line sealing machines since 1941. The best available components/engineering are provided with each Foil Sealers giving you long- term, low maintenance bottling, and packaging equipment. Complete bottle orienting, cleaning, filling, capping, sealing and diagnostic systems including.

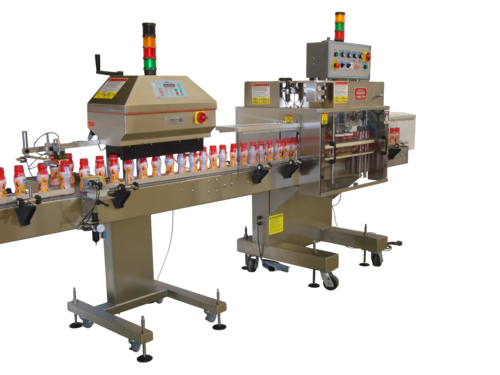

Automatic Waterless Induction Foil Sealers

AutoMate’s Proven SMART SEAL® Waterless Cap Sealers®. Accommodates All Your Sealing Needs While Outperforming All Others – From the Originator of the “Waterless Cap Sealer® “

“WATERLESS” – NO WATER COOLING REQUIRED – Eliminated radiators, pumps, fan belts, water tubing, water corrosion, spills.

Standard Stainless Steel Portable Design – Ideal for all industries including: pharmaceutical, food, chemicals, beverages, cosmetics, etc.

Ultra-Compact – Minimal space requirements. The smallest most powerful WATERLESS CAP SEALERS in the industry.

High Efficiency – Exclusive design puts the power into sealing, not into wasted heat requiring water cooling. Lower wattage required for most applications. Built-in power save mode minimizes energy consumption based on line speed and production use.

User-Friendly – An all-digital control panel allows the operator to easily set-up and operates sealer for quick changeovers. Exclusive features such as menus, recipes, sensors and indicator lights allow for quick set-ups. No moving parts. No tools required. Remote controls are available. Capable of handling most containers and caps on one machine

Complete Line Integration – Accomplished with a built-in microcomputer at no extra cost. This allows interfacing with other in-line equipment. AutoMate offers remote control, RS-232 interface, statistical analysis retrieval, missing foil detection and rejection, skewed cap, loose cap, missing cap and stalled bottle detection, etc.

Competitive Pricing – The AutoMate sealers are priced to be well within everyone’s budget. They are the most competitively priced, built to last sealers with more standard and advanced features than any other sealer available. AutoMate uses stainless steel where others use aluminum and/or plastic.

Unsurpassed Performance – Leading- edge technology and designs minimize power consumption. Over 16 years of extensive Research and Development has led to AutoMate’s exclusive patented design and features, setting AutoMate apart from other “Waterless” sealer imitations. Our Sealer Technology is protected by over 9 patents surpassing other similar machines in reliability and performance, making your production line more efficient.

Versatile – Accommodates all container materials including: PE, PP, PET, PS, PVC, Metal and Glass. Seals all cap materials, including plastic and metal.

IQ-OQ- Professionally prepared validation and documentation assistance available to suit your exact needs.

Hi-Tech Microprocessor – Controls and compensated sealing power – detects low power conditions/brownouts – automatically adjusts for varying loads to maintain correct sealing power. Indicator LEDs display setup and machine status. Over 23 possible faults are displayed on an LED screen.

Maximum Power Output – Beware of inexpensive sealers that offer 2KW of power or less. The Model AM-250 and Model AM-500 offers more output power than other “Waterless” sealer available today. Maximum power output enables the user versatility for difficult applications and the ability to meet future production requirements.

Self-Calibration – All sealing machines containing electronics need to be calibrated. ONLY AutoMate Sealers have a built-in “STANDARD” calibration feature to verify that the sealer is performing to its maximum requirements and accuracy based on YOUR line voltage.

FAQs

Contact KAPS-ALL or a KAPS-ALL Sales Representative. KAPS-ALL's experienced staff can guide you in choosing the model that fits your current and future needs.

You can purchase a KAPS-ALL product directly from KAPS-ALL or from a local KAPS-ALL Sales Representative. KAPS-ALL offers a free demonstration and testing of your product before you buy at no cost or obligation.

KAPS-ALL simple patented machine designs can usually be serviced by your own staff. KAPS-ALL's local representatives and factory technicians are also available.

A complete inventory of parts are available for immediate shipment.