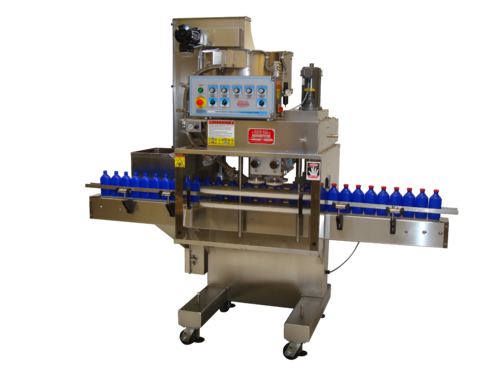

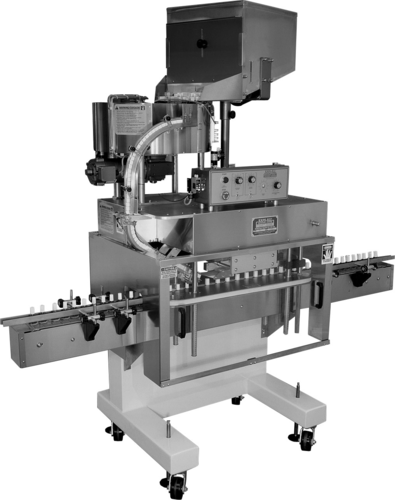

Capping Machines

Capping machines produced since 1941. Kaps-All currently offers over 12 models to suit your packaging needs.

KAPS All offers a wide variety of capping machine equipment to secure most cap types onto a wide assortment of bottle types. Our capping machines utilize the state of the art technologies to achieve the highest speeds and most accurately capped bottles on the market. We manufacture different styles of capping machines. Our capping machinery is available from a low rate capping up to a high-speed capping system.

Why choose KAPS-ALL® for Capping Machines?

KAPS-ALL Packaging System, Inc. has been designing and building top of the line sealing machines since 1941. The best available components/engineering are provided with each Capping Machines giving you long- term, low maintenance bottling, and packaging equipment. Complete bottle orienting, cleaning, filling, capping, sealing and diagnostic systems including.

AutoMate Technologies®, the originator of the “Waterless Cap Sealer®” introduces a combination in-line automatic labeling machine. This pressure-sensitive labeler has been engineered for front and back flat panel applications and also round bottle wrap applications on plastic, metal, fiber and glass containers. Kaps All specializes in capping machines and cap feeding systems for both startup companies as well as higher speed production environments.

Outstanding Features Offered Only by Kaps-All Packaging Systems

With a focus on capping machines, we are proud to present the following unique features:

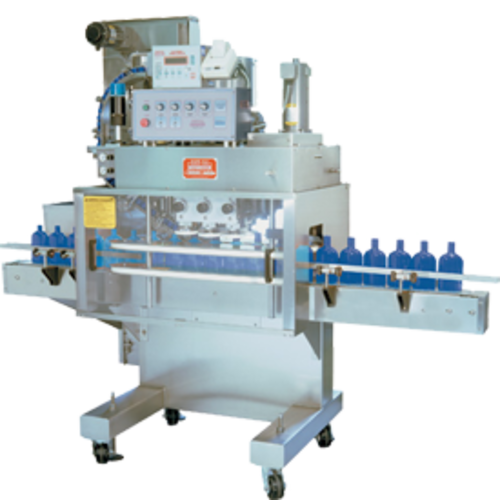

- No changeover parts are necessary for standard caps and containers. Knob adjustments regulate the fast changeover of virtually any size and shape cap including: tamper evident caps, child safety caps, overcaps and dispenser caps.

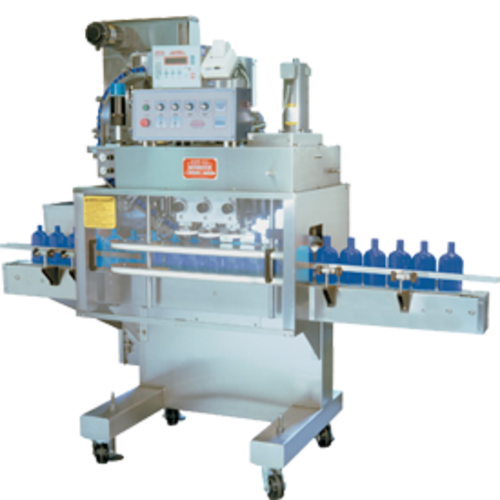

- Standard stainless steel components include: upper and lower cap chutes, cap supply hopper, guarding throughout, rotary feeder, conveyor frame, shafting, screws, gripper housings, etc.

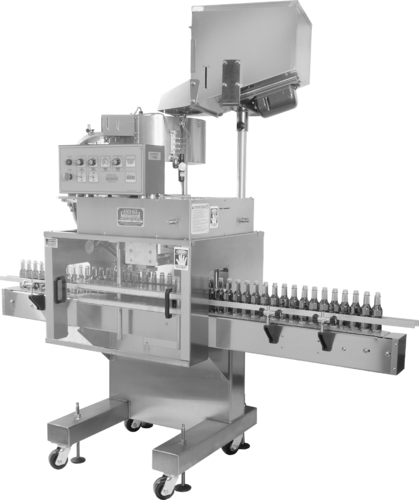

- Handles vials to 2-1/2 gallon containers, made of plastic, glass or metal without changeover parts for standard containers.

- No bottle - no cap safety release.

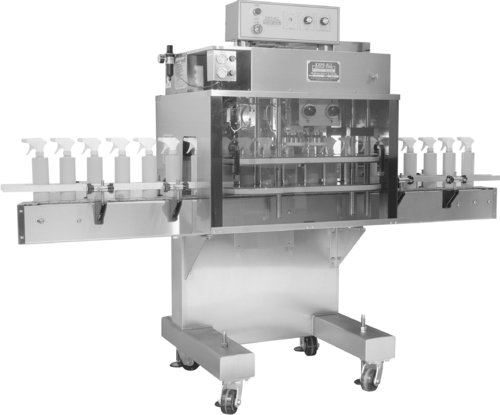

- All capping machines come standard with the exclusive Feed Systems® patented stainless steel rotary cap feeder offering quiet and gentle cap orientation with no changeover parts for all standard caps.

- All models are available with two sets of bottle gripper belts for tall or unstable containers providing complete bottle control, consistent torque and eliminating product spillage and cross-threading.

- Fully adjustable bottle gripper assemblies are available to accommodate various bottle contours including tapered containers and containers with offset necks.

- All models can be fitted with several types of cap feeders and elevators such as the standard Feed Systems® rotary cap feeder or a vibratory cap feeder to accommodate your production requirements.

- Floor level Bulk Cap Elevators and Mini-“L” cap elevators are available for all models to accommodate higher speed requirements and restricted ceiling heights.

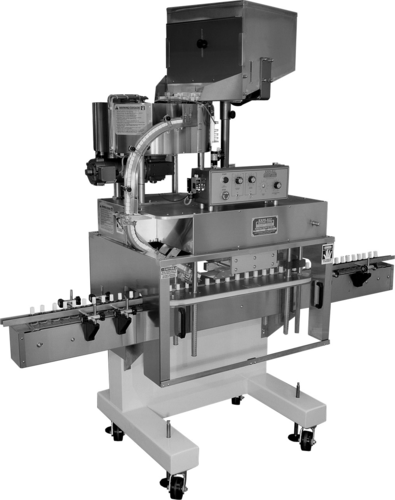

- The exclusive “Dial-A-Torque”® patented clutch system is standard equipment on all models. This heavy-duty clutch system provides a consistent torque for 8mm to 120mm diameter caps of all types and is completely adjustable. (Available as a patented remotely controlled pneumatic system).

- Exclusive Kaps-All Electronic Torque Monitoring System is available for all models, providing a high level of quality assurance. Computer interface (RS-232 and/or USB) is standard for auxiliary functions and data printouts.

- All models are capable of being used as cap tighteners for all types of spray pumps, short runs, specialty caps, and re-torquing after heat induction foil sealing.

- All front and rear changeover adjustments move together on center with calibrated knob settings. No need to adjust the machine from behind. Positive centering of your caps and containers eliminate cross-threaded caps, misalignments and undue wear of cap tightening discs.

- Minimum amount of moving parts are used to reduce maintenance, prevent expensive downtime, avoid loss of production and eliminate the need for skilled mechanics. Parts are kept in stock for immediate delivery.

- NEMA 12 wiring is standard. Hazardous location wiring and other electrical requirements are available on all models.

- All capping machines are guaranteed for a full 2 years–the longest in the industry.

- All capper models are continuously in production prior to your order enabling us to provide fast delivery.

- Portable bases available for all models.

- Left to right conveyor travel is standard–right to left models are available.

Kaps-All Packaging Systems, Inc., is your single source for all your bottle orienting, unscrambling, cleaning, filling, capping, induction sealing, conveying, parts feeding, torque testing/torque monitoring, inspecting, labeling and accumulating needs. Other available equipment includes modular conveyor systems, de-capping, gas purging, bench model torque meters, liquid fillers, parts orienting and custom packaging machinery.

FAQs

Contact KAPS-ALL or a KAPS-ALL Sales Representative. KAPS-ALL's experienced staff can guide you in choosing the model that fits your current and future needs.

You can purchase a KAPS-ALL product directly from KAPS-ALL or from a local KAPS-ALL Sales Representative. KAPS-ALL offers a free demonstration and testing of your product before you buy at no cost or obligation.

KAPS-ALL simple patented machine designs can usually be serviced by your own staff. KAPS-ALL's local representatives and factory technicians are also available.

A complete inventory of parts are available for immediate shipment.