FA-PG-E Pressure Gravity Filler

Liquid Fillers

Model FA-PG

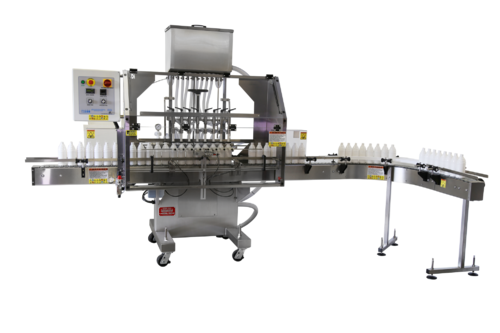

Expandable Fills-All Model FA-PG Pressure / Gravity Filler

-Fully Automatic, Microprocessor controlled, straight line liquid filling machine. Handles glass, plastic or metal containers. Handles all free flowing liquids (excellent with foaming thin products). Great for filling lines with multiple products.

Description

Introducing the Expandable Fills-All Model FA-PG Pressure/Gravity Filler, a fully automatic, microprocessor-controlled liquid filling machine that can handle all free-flowing liquids with ease. This straight-line filler is perfect for filling lines with multiple products and can accommodate glass, plastic or metal containers ranging from 1-3/4 inches high to 1 gallon containers.

The Model FA-PG comes equipped with two stainless steel gravity/pressure nozzles, which are adjustable for varying fill heights and can be expanded to 18 nozzles. This versatile machine is capable of handling both free-flowing and most viscous liquids, making it excellent for foaming thin products. The pressure gauge on the manifold ensures a sanitary design, and FDA approved tubing is provided for all nozzles.

The FA-PG is built to last, with standard one-piece welded stainless steel construction cabinet, and a portable design on four heavy-duty swivel casters. Its master control wheel allows for height adjustment of all nozzles by a single turn, ensuring fast and repeatable settings between changeovers. The machine's left-to-right conveyor travel is standard, but right-to-left travel can be indicated on purchase orders.

The FA-PG also comes with a range of features to ensure optimal performance, including a totally adjustable pneumatic stainless steel cylinder bottle gating system, a fill bottle counter to keep track of the number of bottles being filled in a given run, and a nozzle rack with height-adjustable screw made of stainless steel. The machine has a stainless steel two-port pressure manifold for pressure mode and a 20-gallon upper product supply tank for gravity mode, as well as a 20-gallon product supply/overflow lower tank for both gravity and pressure mode.

This automatic liquid filling machine is microprocessor-controlled, making it easy to use, and requires minimal conveyor space of either 44 inches or 59 inches with the control box. With no changeover parts for all similar neck finish containers and all product contact parts made of stainless steel or plastic, the FA-PG is a reliable and versatile machine that will meet your liquid filling needs.

In summary, the FA-PG-E Pressure Gravity Filler is a top-of-the-line, fully automatic, and versatile liquid filling machine designed to handle all free-flowing liquids, including thin foaming products. With a range of features such as adjustable nozzles, bottle gating system, and fill bottle counter, it ensures optimal performance and reliability. Its portable design, microprocessor control, and compatibility with various container materials make it a great investment for any business looking for an efficient and cost-effective liquid filling solution.

Features:

The Model FA-PG Pressure/Gravity Filler comes equipped with the following standard features at no charge.

- Two stainless steel gravity/pressure nozzles adjustable for varying fill heights (expandable to 18 nozzles)

- Accommodates a bottle range of 1-3/4 inch high to 1 gallon containers.

- Handles glass, plastic or metal containers.

- Handles free flowing and most viscous liquids (excellent with foaming products).

- Pressure gauge on manifold (sanitary design).

- FDA approved tubing provided for all nozzles.

- Standard one piece welded stainless steel construction cabinet.

- Mounting facilities for optional conveyor or can overhang existing conveyor.

- No bottle-no fill safety monitor.

- Nema 4 (wash down) control panel.

- Totally adjustable pneumatic, stainless steel cylinder bottle gating system.

- Portable on four heavy duty swivel casters.

- Master control wheel permitting height adjustment of all nozzles by a single turn assuring fast, repeatable settings between changeovers.

- Left to right conveyor travel is standard. For right to left travel, please indicate on your purchase order.

- Standard wiring-110V, 1 Phase, 60 Hz, utilizing approximately 1-3 CFM of air (more with diaphragm pumps).

- Fill bottle counter to keep count of the number of bottle being filled in any given run.

- Nozzle rack, height adjustable screw, to be stainless steel.

- Stainless steel two-port pressure manifold sanitary design (for pressure mode).

- 20 gallon upper product supply tank (for gravity mode).

- 20 gallon product supply/overflow lower tank (gravity and pressure mode).

- Two full year guarantee on all parts, less tubing, seals and gaskets (electronics are covered under manufacturers guarantee).

- Air filter/regulator and air supply switch.

- Microprocessor controlled for ease of use.

- Requires minimal conveyor space 44 inch or 59 inch with control box.

- No changeover parts for all similar neck finish containers.

- All product contact parts to be stainless steel or plastic.

Ideal For:

All liquid filling applications. The diversity of having 2 machines in 1. Excellent with thin and slightly viscous foaming products.

The fillers offer accuracy, repeatability and ease of use with little or no changeover parts State-of-the-art components offer maximum performance, reliability and versatility to keep pace with your production requirements. FILLS-ALL fillers can operate separately or can be integrated into a complete packaging system.

Air-Electrical:

-110V, 1 Phase, 60 Cycle

- Air: 1-2 cu/ft per min. 90psi.

Size:

- Base Crated Weight: 850 lbs

- Crated Dimension: 8’x4’x7’4” W