FE4 Portable 4 Spindle Cap Tightener

Cappers, and Capping Machines

FE4 Portable 4 Spindle Cap Tightener: Optimized Efficiency for Versatile Packaging

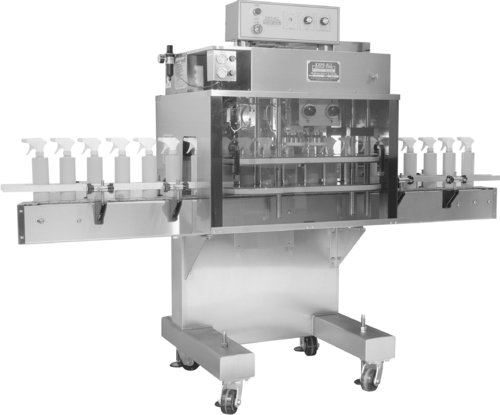

Kaps-All Packaging Systems introduces the Model FE4 Portable 4 Spindle Cap Tightener & Retourquer. This advanced machine brings top-tier efficiency to your packaging line with speeds reaching up to 200 bottles per minute. Known for its compact design, the FE4 needs a mere 32" of line space, providing optimum productivity without compromising on space.

High-Performance Packaging for a Range of Containers

Our machine is perfect for Pump & Trigger Cap Tightening and Retourquing after heat induction sealing. With its capacity to handle a variety of containers, from low jars and vials up to 2-1/2 gallon containers, this capping machine can effortlessly manage metal, glass, or plastic containers. Portability is an added perk, making it easy to move from one production line to another for maximum versatility.

Standard Features: Strength, Precision, and Durability

The FE4 Semi-Automatic Capper is loaded with standard features that distinguish it in the marketplace. With an impressive two-year guarantee on all parts, it assures durability and reliability. The machine's patented design eliminates the need for changeover parts for a broad range of standard caps and container shapes and sizes, streamlining operations.

Built for endurance, the capper is outfitted with a stainless steel 7’6” conveyor frame and a stainless steel enclosure with Lexan doors. This, combined with its stainless steel bolts and fasteners, makes for a robust machine ready to withstand demanding operations. Moreover, electronically controlled variable speed drives ensure smooth adjustments and optimal control.

User-Friendly Operation

The FE4 is designed for user-friendliness. Calibrated settings enable effortless and repeatable changeovers, and mounting facilities are provided for using a second set of bottle gripper belts. The machine is portable on four swivel wheels for easy maneuvering, and all parts are modularized for quick replacement, requiring little to no tools. Safety is paramount, with interlocking safety switches on Lexan guarding enclosure ensuring the machine will not run unless the doors are closed.

Customizable Options

Enhance your capper's capabilities with our variety of options. Choose from features like a stainless steel frame and cabinet table top plate, motorized capper head height adjustment, or the EM-980 Electronic Torque sensor, which records torques from the torque sensor onto paper. You can also choose to have an audible alarm and yellow flashing light indicator for low torque. With these options and more, customize your machine to best fit your operational needs.

Technical Specifications

The FE4 Cap Tightener operates on a 110V 1Ph 50/60Hz power supply (NEMA 12) and requires minimal air for the pneumatic clutch option. The base machine dimensions are 32”, and when crated, the machine measures 8' L x 4' W x 6' 8" H and weighs 850 lbs.

With the Model FE4 Portable 4 Spindle Cap Tightener & Retourquer, Kaps-All Packaging Systems brings you an efficient and versatile solution to meet your packaging needs. Invest in this machine for a smoother, more efficient packaging operation.

Features:

THE MODEL “FE4” SEMI-AUTOMATIC CAPPER COMES EQUIPPED WITH THE FOLLOWING STANDARD FEATURES AT NO CHARGE:

- Two full-year guarantee on all parts.

- Stainless steel 7’6” conveyor frame DC variable speed drive with a 4 1/2” wide Delrin chain with stainless steel pins, stainless steel drive and idler shafts with patented reinforced nylon and stainless steel conveyor rail posts, stainless steel conveyor end guards and non-corrosive drive and idler conveyor top chain sprockets (left to right travel standard). Note: (Machine also can be purchased without conveyor).

- Stainless steel enclosure with Lexan doors on front and back enclosing spindle and gripper section down to conveyor.

- Patented design eliminates need for changeover parts for a wide range of standard caps, container shapes and sizes.

- Calibrated settings allow for ease and repeatability of changeovers.

- Stainless steel guarding of upper drive section.

- One pair of stainless steel bottle gripper belt housings complete with belts and drives.

- All stainless steel bottle gripper belt and spindle shafting.

- Heavy duty patented multiple disc adjustable torque clutches which will give a consistent torque and minimize wear on cap tightening discs (two pair).

- All electronically controlled variable speed drives for ease of adjustments.

- All Nema 12 electrical components.

- Portable on four swivel wheels for easy maneuvering.

- Mounting facilities provided for using a second set of bottle gripper belts.

- One piece solid welded construction cabinet epoxy painted for both cleanliness and easy maintenance.

- Stainless steel machine leveling screws with floor pads.

- All parts modularized for quick replacement. Little to no tools required.

- All stainless steel bolts and fasteners throughout.

- Interlocking safety switches on Lexan guarding enclosure so machine will not run unless doors are closed

Ideal For:

- Ideal for Pump & Trigger Cap Tightening and

- Retourquing after heat induction sealing.

- Vials up to 2-1/2 gallon containers

- Speeds up to 200 bottles/minute

Air-Electrical:

-110V 1Ph 50/60Hz (NEMA 12)

- Minimal Air required for pneumatic clutch option.

Size:

- Base Machine Dimension: 32”

- Crated Dimension: 8' L x 4' W x 6' 8" H

- Crated Weight: 850lbs.