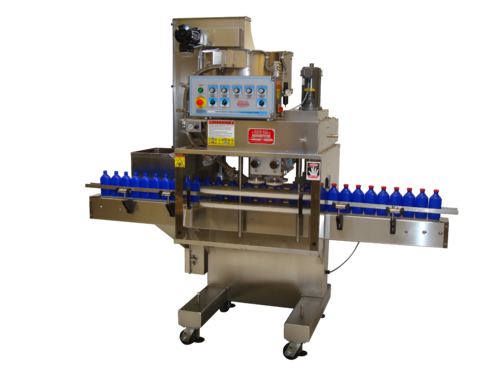

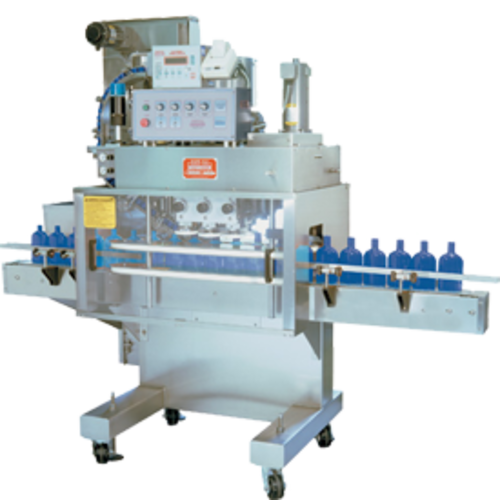

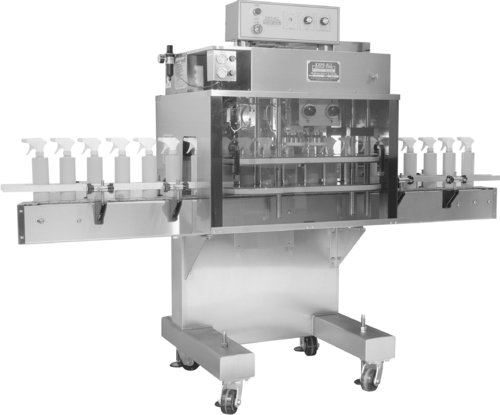

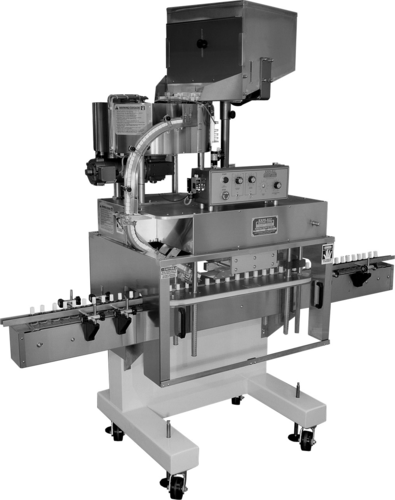

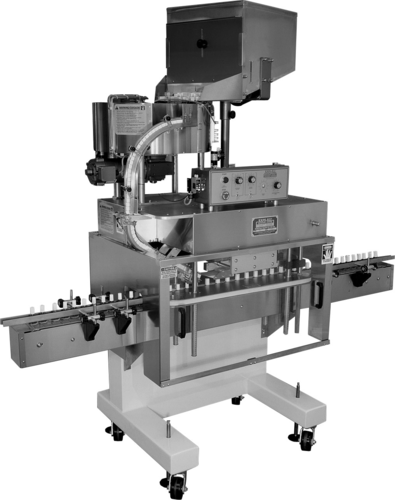

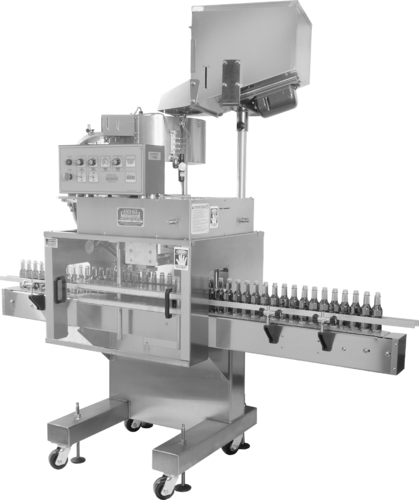

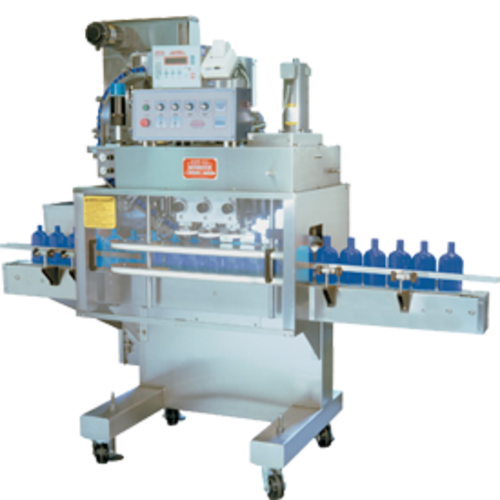

Cappers

Capping machines produced since 1941. Kaps-All currently offers over 12 capping machine models to suit your packaging needs.

Our State-Of-The-Arts KAPS-ALL® Capping machines have been produced and perfected since 1941. KAPS-ALL® currently offers over 12 capping machine models to suit your packaging needs.

Our wide range of models models support capping of various sizes such as 8mm to 120mm diameter along with standard flat caps to yorker and other specialty caps. Our cappers can handle from short jar up to 18” tall 2.5 gallon jugs. Asymmetrical and symettrical bottles and more! We can support capping for bottles/cans, ampoules/vials, cups, bowls, tubs, bottles/ jars. Additionally, we offer 4 levels of automation: automatic, semi-automatic, manual, pilot/lab. Our machines easily integrate into an existing line or can come integral with a conveying system. We proudly can support the following cappers: Press-on cappers, screw cappers, retorquers, overcappers and other specialty applications. We have spindle cappers, belt cappers, and chuck style cappers! Choosing the right capping machine for your production line is incredibly important and can make all the difference in a productive packaging line

With over 83 years of excellence producing capping machines you can trust KAPS-ALL® to automate and streamline your production line. Our 12 models can provide a solution to varying needs with top notch quality.

Look below to learn more about our 12 different models so that you can compare to find the model that fits your needs:

Why choose KAPS-ALL® for Cappers?

KAPS-ALL Packaging System, Inc. has been designing and building top of the line sealing machines since 1941. The best available components/engineering are provided with each Cappers giving you long- term, low maintenance bottling, and packaging equipment. Complete bottle orienting, cleaning, filling, capping, sealing and diagnostic systems including.