ECF-G Electronically Controlled, Timed Volumetric Filler

Liquid Fillers

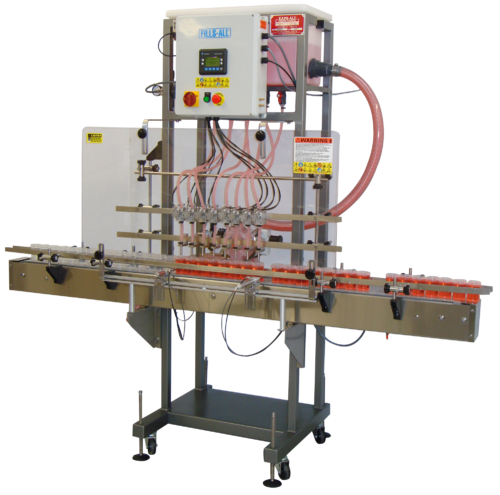

Model ECF-G: Electronically Controlled, Timed Volumetric Filler

Premium Design for Optimal Functionality

The Model ECF-G, brought to you by Kaps-All Packaging Systems, is a unique, single head gear pump filler known for its versatility and accuracy. It features a robust, all stainless steel enclosure that houses a product supply gear pump and a solitary nozzle. This model is complete with an adjustable nozzle rack and state-of-the-art electronic controls that allow for precision, speed, and reliability in your filling operations. The portable design of this model ensures maximum flexibility, bringing top-tier filling capabilities right where you need them.

Enhanced Features

The Fills-All Model ECF-G comes outfitted with a multitude of innovative features designed to deliver reliable, efficient, and precise filling. It holds up to four nozzles that can be expanded to eight or more to suit your specific requirements. Controlled by a programmed electronic microprocessor, the filling system ensures fast, repeatable changeovers, reducing downtime and increasing productivity.

The unit boasts a “no bottle-no fill” function which is electronically controlled and directly linked to the microprocessor, thereby ensuring that no product is wasted. Furthermore, a convenient LED readout module displays a bottle/cycle counter, aiding in efficient tracking and monitoring of your filling operations.

To ensure a continuous product supply, the model features a 20-gallon high-density polyethylene supply tank. A variety of nozzle and valve styles are available, including diaphragm and pinch valve types, providing easy cleaning, sanitary filling, and accurate dispensing.

Versatile and User-Friendly Design

The stainless steel nozzle rack is fully adjustable in height to accommodate containers ranging from 1/4" to 20" tall. The nozzles are conveniently adjustable along a track, allowing easy adaptation to any bottle opening.

Moreover, this model is highly portable and mobile, facilitated by casters. Once in line, the filler is secured with elevating screws and floor pads. With an electronic access module that is panel mounted, you can adjust fill volume on an LED digital display without opening the electrical box. Its compact design requires only four square feet of floor space, saving valuable room in your facility.

Superior Safety and Maintenance Features

To protect the controls from wetted areas, a NEMA 4 electrical enclosure is incorporated in the design. The frame of the ECF-G is coated with stainless steel pigmented USDA epoxy for cleanliness and easy maintenance. For added assurance, Kaps-All provides a two-year parts guarantee, excluding tubings and seals.

Cleaning is a breeze with this model, requiring less than five minutes without the need for disassembly. In case of parts replacement, the modularized design allows for quick and easy plug-in replacements.

Diverse Options and Specifications

A range of options are available, including extra nozzles, an automatic bottle indexing system, and an electronic level sensor for the supply tank. The model can be fitted with a polypropylene double diaphragm 37 GPM pump with Teflon valves or a stainless steel frame.

Model ECF-G is ideally suited for all free-flowing corrosive products. It operates on 120V, 1 Phase, 60 Cycle, and requires 1 cu/ft per min. 90psi. The base crated weight of the model is 650 lbs, and the crated dimensions are 8’x4’x7.3’ W.

Upgrade your filling operations with the ECF-G Electronically Controlled, Timed Volumetric Filler – a symbol of quality and efficiency from Kaps-All Packaging Systems.

Features:

The Fills-All Electronically Controlled Flow Automatic Liquid Filler Model "ECF-G” comes equipped with the following:

- Four nozzles (expandable to 8 or more)

- A filling system controlled entirely by a programmed electronic microprocessor ensuring repeatable and fast changeovers

- No bottle-no fill electronic controls coupled directly to the microprocessor

- Bottle/Cycle counter displayed on an LED readout of access module to keep track of bottles being filled

- 20 gallon high density polyethylene supply tank

- Nozzles and valves are available in several styles and materials. Diaphragm and pinch valve types for easy cleaning, sanitary filling and accurate dispensing

- Stainless steel nozzle rack fully adjustable in height to accommodated 1/4" tall container to 20" tall container. The nozzles are easily adjustable along a track to adjust to any bottle opening

- Portable on casters for complete mobility comes complete with elevating screws and floor pads once the filler is placed in line

- The electronic access modular is panel mounted allowing for adjustment so fill volume to be made on an LED digital display without the need to open the electrical box

- Nema 4 electrical enclosure protects all controls from wetted areas

- Two full year parts guarantee (excluding tubings an seals)

- Frame is stainless steel pigmented USDA epoxy coated for both cleanliness and easy maintenance

- All parts modularized for quick plug in replacement

- Cleans in less than five (5) minutes. No disassembly required

- Requires only four square feet of floor space

- Special models available for special filling applications. Please inquire for assistance.

Ideal For:

All free flowing corrosive products.

Air-Electrical:

-120V, 1 Phase, 60 Cycle

- Air: 1 cu/ft per min. 90psi.

Size:

- Base Crated Weight: 650 lbs

- Crated Dimension: 8’x4’x7.3’ W