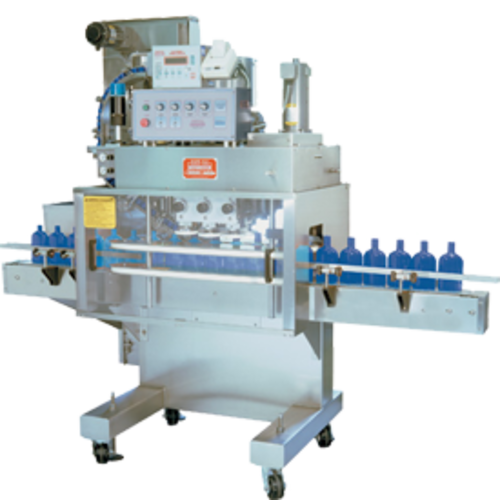

A6 6 Spindle Auto. Capper

Cappers, and Capping Machines

Kaps-All Packaging Systems A6 6-Spindle Automatic Capper: A Comprehensive Overview

Our model A6 Portable 6 Spindle Capper is a paramount addition to any industrial packaging line. With speeds up to 200 BPM, this fully automatic capper is designed to handle screw caps of all materials and styles ranging from 8mm to 120mm. It's proficient in handling pilfer evident and child-resistant cap closures within a standard range of 13mm to 70mm, and is compatible with metal, glass, or plastic containers, from low jars and vials up to 2-1/2 gallons. Not only does it cap but also doubles as a cap and pump tightener. The A6 Capper comes with a standard rotary cap feeder, with an optional escalator cap feeder also available.

Superior Features

The A6 Capper is packed with standard features, all at no extra charge. These include a two-year full guarantee, a stainless steel 7’6” conveyor frame, a DC variable speed drive, a 4 1/2” wide Delrin chain, and stainless steel pins. The machine is enveloped in a stainless steel enclosure with Lexan doors on the front and back, enclosing the spindle and gripper section down to the conveyor. No changeover parts are required for a broad range of standard cap sizes and container shapes, ensuring easy adaptation to any production line. The A6 Capper also boasts of a stainless steel 3.5 cubic foot cap supply hopper and a stainless steel guarding of the upper spindle section.

All the key machine elements, from bottle gripper belt housings, spindle shafting to multiple disc adjustable torque clutches, are designed with stainless steel. To ensure optimal flexibility, the A6 Capper is portable on four swivel wheels and features a solid one-piece welded construction cabinet painted white epoxy for both cleanliness and easy maintenance.

Optional Features

To further enhance its performance, the A6 Capper can be equipped with an array of optional features. These include a 36” rotary cap feeder, stainless steel frame and cabinet, nickel or chrome-plated visible painted surfaces above the conveyor, and an EM-980 Electronic Torque sensor. Other options include a mini-L stainless steel low profile hopper/elevator, a stainless steel bulk elevator, and conveyor extensions.

Ideal for a Variety of Applications

The A6 Capper shines in various packaging applications. Whether you're capping vials or large 2-1/2 gallon containers, the A6 Capper guarantees optimal performance. Its versatility is well-suited for caps of all materials ranging from 8mm to 70mm, and can effectively work at speeds up to 300 bottles per minute.

Technical Specifications

In terms of power requirements, the A6 Capper operates at 220V, 3Ph 50/60Hz (NEMA 12), and requires an air supply of 2 to 4 cubic ft/min. The base machine measures 38” in dimensions, while the crated dimension is 8' L x 4' W x 6' 8" H and weighs around 1300lbs when crated.

The A6 Capper - A Blend of Efficiency and Precision

With a reputation for durability, efficiency, and precision, the A6 Capper is a reliable solution for all your capping needs. Contact Kaps-All Packaging Systems today to learn how the A6 Capper can enhance your production line's efficiency and reliability.

Features:

THE MODEL “A6” CAPPER COMES EQUIPPED WITH THE FOLLOWING STANDARD FEATURES AT NO CHARGE:

- Two full-year guarantee.

- Stainless steel 7’6” conveyor frame DC variable speed drive with a 4 1/2” wide Delrin chain stainless steel pins, stainless steel drive and idler shafts with reinforced nylon conveyor rail posts, stainless steel conveyor end guards and non-corrosive drive and idler conveyor top chain sprockets. Note: (Machine also can be purchased without conveyor).

- Stainless steel enclosure with Lexan doors on front and back enclosing spindle and gripper section down to Conveyor.

- No changeover parts needed for a wide range of standard cap sizes, container shapes and sizes.

- Stainless steel adjustable upper and lower cap chutes to handle from 13mm to 70mm standard flat CT caps.

- Stainless steel 3.5 cubic foot cap supply hopper (pre-feeder).

- Stainless steel guarding of upper spindle section.

- One pair of stainless steel bottle gripper belt housings with belts and drives.

- All stainless steel bottle gripper belt and spindle shafting.

- Heavy duty patented multiple disc adjustable torque clutches which will give a consistent torque and minimize wear on cap tightening discs (one pair).

- All D.C. electronically controlled variable speed drives.

- All Nema 12 electrical components.

- Portable on four swivel wheels for easy maneuvering.

- Mounting facilities for using a second set of bottle gripper belts.

- One-piece solid welded construction cabinet painted white epoxy for both cleanliness and easy maintenance.

- All rotary cap feeders have stainless steel and FDA approved materials for all contact parts.

- Air filter-regulator for feeder.

- Stainless steel machine leveling screws with floor pads.

- No bottle/no cap release from chute.

- All parts modularized for quick replacement.

- All stainless steel bolts and fasteners throughout.

- Interlocking safety switches on Lexan guarding enclosure so machine will not run unless doors are closed

Ideal For:

- Caps of all materials from 8mm-70mm.

- Vials up to 2-1/2 gallon containers

- Speeds up to 300 bottles/minute

Air-Electrical:

-220V, 3Ph 50/60Hz (NEMA 12)

- Air 2 to 4 cubic ft/min

Size:

- Base Machine Dimension: 38”

- Crated Dimension: 8' L x 4' W x 6' 8" H

- Crated Weight 1300lbs