BE4 Overcapper / Lidder

Cappers, and Capping Machines

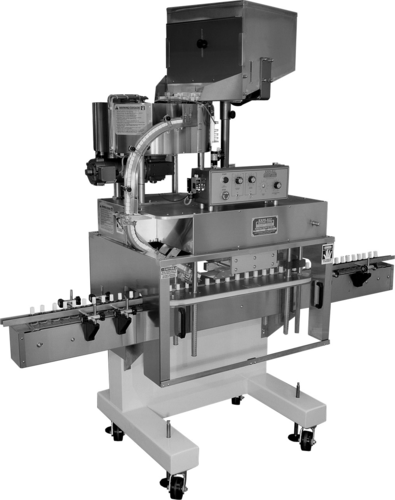

Kaps-All Packaging Systems: Model BE4 Overcapper / Lidder

Welcome to the most efficient solution for all your over capping and lidding needs - the BE4 Overcapper / Lidder from Kaps-All Packaging Systems. Our Model BE4 Portable Over Capper / Lidder seamlessly manages over caps, lids, and fitments made of any material from 13mm to 70mm, offering the versatility required in a fast-paced production environment.

Unmatched Speed, Compactness, and Versatility

With the capacity to reach speeds of up to 200 bottles per minute (BPM), the BE4 Overcapper / Lidder ensures high-speed processing without sacrificing precision or efficiency. Despite its powerful performance, the machine demands just 33 1/2" of line space, making it an ideal choice for facilities where space is a premium.

This machine offers unmatched versatility, handling metal, glass, or plastic containers, from low jars and vials up to 2-1/2 gallons. Its portability feature allows for easy mobility from one production line to another, providing the flexibility required to meet the changing demands of the production schedule. A standard rotary cap feeder is included with each unit.

Feature-Rich and Robust

The BE4 Overcapper / Lidder comes fully equipped with a multitude of standard features, all designed to ensure robust, reliable operation. We offer a two-year full guarantee on all parts, highlighting our confidence in the machine's quality and longevity.

Built with a stainless steel 7'6" conveyor frame and a host of other stainless steel components, the BE4 ensures the highest degree of durability and hygiene. It features patented designs that eliminate the need for changeover parts for a wide range of standard caps and container shapes and sizes, enhancing productivity and reducing downtime.

All parts are modularized for quick replacement, and the machine is portable on four swivel wheels for easy maneuvering. Furthermore, it has interlocking safety switches on its Lexan guarding enclosure, ensuring the machine will not run unless the doors are closed - a vital feature for maintaining a safe work environment.

Customizable to Your Specific Needs

The BE4 Capper can be further enhanced with various optional features, including a stainless steel frame and cabinet, motorized capper head height adjustment, and stainless steel Bulk Elevator. You can also opt for nickel or chrome plating for all visible painted surfaces above the conveyor.

Ideal for a Wide Range of Applications

Whether you're dealing with caps of all materials from 8mm-70mm, or vials up to 2-1/2 gallon containers, the BE4 Overcapper / Lidder is your solution. It is capable of handling speeds up to 80 bottles per minute.

Specifications

Running on 110V 1Ph 50/60Hz (NEMA 12) and requiring 2 to 4 cubic ft/min of air, the BE4 Overcapper / Lidder delivers a potent blend of efficiency and performance. The base machine dimensions are 32”, while the crated dimension measures 8' L x 4' W x 6' 8" H, weighing in at 1300lbs.

Experience the BE4 Overcapper / Lidder difference today - where speed, versatility, and robust construction meet to deliver outstanding packaging performance.

Features:

THE MODEL “BE4” OVER-CAPPER / LIDDER COMES EQUIPPED WITH THE FOLLOWING STANDARD FEATURES AT NO CHARGE:

- Two full-year guarantee on all parts.

- Stainless steel 7’6” conveyor frame DC variable speed drive with a 4 1/2” wide Delrin chain with stainless steel pins, stainless steel drive and idler shafts with reinforced nylon conveyor rail posts, stainless steel conveyor end guards and non-corrosive drive and idler conveyor top chain sprocket.(left to right travel standard) Note: (Machine also can be purchased without conveyor).

- Stainless steel enclosure with Lexan doors on front and back enclosing spindle and gripper section down to conveyor.

- Patented design eliminates need for changeover parts for a wide range of standard caps, container shapes and sizes.

- Patented stainless steel adjustable upper and lower cap chutes to handle from 13mm to 70mm standard flat CT caps.

- Calibrated settings allow for ease and repeatability of changeover.

- Stainless steel 3.5 cubic foot upright cap supply hopper (pre-feeder).

- Stainless steel guarding of upper drive section.

- One pair of stainless steel bottle gripper belt housings complete with belts and drives.

- All stainless steel bottle gripper belt and spindle shafting.

- All electronically controlled variable speed drives for ease of adjustment.

- All Nema 12 electrical components.

- Portable on four swivel wheels for easy maneuvering.

- Mounting facilities for using a second set of bottle gripper belts.

- One piece solid welded construction cabinet epoxy painted for both cleanliness and easy maintenance.

- All rotary cap feeders have stainless steel and FDA approved materials for all contact parts.

- Air filter-regulator for feeder.

- Stainless steel machine leveling screws with floor pads.

- No bottle/no cap release from chute.

- All parts modularized for quick replacement. Little to no tools required.

- All stainless steel bolts and fasteners throughout.

- Interlocking safety switches on Lexan guarding enclosure so machine will not run unless doors are closed

Ideal For:

- Caps of all materials from 8mm-70mm.

- Vials up to 2-1/2 gallon containers

- Speeds up to 80 bottles/minute

Air-Electrical:

-110V 1Ph 50/60Hz (NEMA 12)

- Air 2 to 4 cubic ft/min

Size:

- Base Machine Dimension: 32”

- Crated Dimension: 8' L x 4' W x 6' 8" H

- Crated Weight 1300lbs