V-8-E Volumetric Piston Filler

Liquid Fillers

Model V-8-E (Formerly Model VOL-32-8)

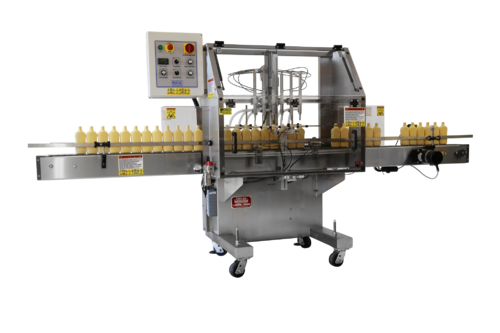

Fills-All Model V-8-E Fully Automatic Volumetric Piston Filler

Accurate to ±0.5%. Easily expandable from 2 to 24 nozzles. Fill volume range of 10-1 with single knob control. Fills free flowing to highly viscous liquids.

Model V-8-E (can handle eight of 36 oz., ten of 20 oz., 12 of all other piston sizes)

Description:

Introducing the V-8-E Volumetric Piston Filler, the ultimate solution for precise and efficient liquid filling. Our fully automatic piston filler is built to handle a range of liquids, from free-flowing to highly viscous substances, with a fill volume range of 10-1 using a single knob control.

Accurate to within ±0.5%, the V-8-E can easily expand from 2 to 24 nozzles, making it perfect for businesses that need to scale up their production. This piston filler can handle eight 36 oz., ten 20 oz., and 12 other piston sizes, providing you with versatile options to accommodate a wide range of container shapes and sizes.

The V-8-E Volumetric Piston Filler comes equipped with numerous standard features to ensure accurate and reliable filling every time. Our programmable microprocessor control allows for repeatable and fast change-overs, while the dual-speed controls provide separate adjustment capabilities for the aspirating and discharge strokes, depending on the product being filled.

Our stainless steel cabinet is built with one-piece welded construction and features bottom-up fill or non-diving nozzles that are adjustable to suit your needs. With a water-tight Nema 4 control box and independent adjustable trimming of pumps to fine-tune each piston, the V-8-E offers you a dependable and streamlined filling process.

Additional features of the V-8-E Volumetric Piston Filler include a stainless steel nozzle rack that is fully adjustable for spacing of nozzles from 1 to 12, an automatic bottle indexing system, a fill bottle counter, and an air filter/regulator and air supply switch. The unit is also portable on four heavy-duty swivel casters, complete with stainless steel leveling screws with floor pads, and has an integral 8'6" long conveyor.

When you purchase the V-8-E Volumetric Piston Filler, you can rest easy knowing that we stand behind our product with a two-year guarantee on all parts (electronics are covered under the manufacturer's guarantee), less tubing, seals, and gaskets.

In summary, if you are looking for a highly efficient, precise, and versatile liquid filling machine, the V-8-E Volumetric Piston Filler is the perfect solution for your business. With its numerous standard features and expandable options, you can easily and reliably meet your liquid filling needs.

Features:

THE MODEL V-8-E VOLUMETRIC PISTON FILLER COMES EQUIPPED WITH THE FOLLOWING STANDARD FEATURES:

- No bottle-no fill.

- Stainless steel cabinet, one piece welded construction.

- Bottom-up fill or non-diving nozzles (adjustable).

- Totally programmed microprocessor control for repeatable and fast change-overs.

- Water tight Nema 4 control box.

- Independent adjustable trimming of pumps to fine-tune each piston.

- Dual speed controls giving separate adjustment capabilities for the aspirating and discharge strokes, depending upon products being filled.

- Portable on four heavy-duty swivel casters, complete with stainless steel leveling screws with floor pads.

- Left to right travel is standard. For right to left travel, please indicate on your purchase order.

- Stainless steel nozzle rack fully adjustable for spacing of nozzles form 1 to 12 nozzles to accommodate virtually every container configuration.

- Stainless steel control box support-offset for easy access and simplified cleaning.

- Fill bottle counter to keep count of the number of bottles being filled in any given run.

- Automatic bottle indexing system-stainless steel construction completely adjustable-accommodates a wide range of container shapes and sizes.

- Air filter/regulator and air supply switch.

- Two-year guarantee on all parts, less tubing, seals and gaskets (electronics are covered under manufacturers guarantee).

- Integral 8'6" long Conveyor.

Ideal For:

All viscous and highly accurate filling applications. Excellent with viscous products.

The fillers offer accuracy, repeatability and ease of use with little or no changeover parts State-of-the-art components offer maximum performance, reliability and versatility to keep pace with your production requirements. FILLS-ALL fillers can operate separately or can be integrated into a complete packaging system.

Air-Electrical:

-110V, 1 Phase, 60 Cycle

- Air: 4-5 CFM @ 90psi.

Size:

- Base Crated Weight: 850 lbs

- Crated Dimension: 9’L x 4’ Wx 6’9” H